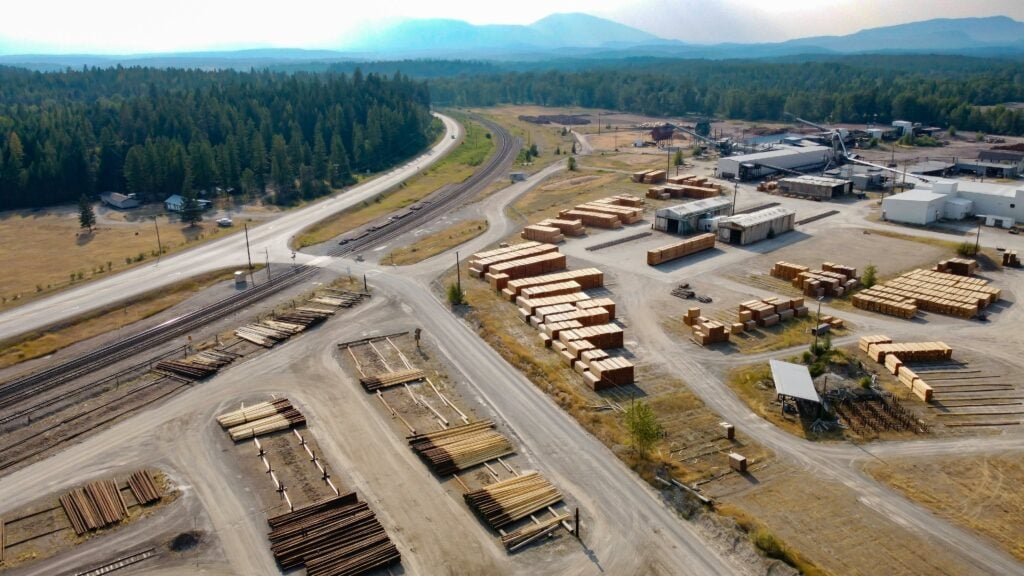

ArcelorMittal’s Saint-Chély-d’Apcher site is France’s only production unit for non-oriented grain electrical steel. The steel produced by ArcelorMittal is heated to over 1000°C to give it its magnetic properties.

The heat produced, previously lost when cooling the steel, is now recovered and reused within the plant, thanks to the installation of two cooling systems (a slow air-contact system and a fast water-contact system).

75% of the energy recovered is now used by the plant, to meet the needs of the industrial process and to heat part of the premises, the halls. Redistributed in a heating network, the recovered calories are also used to produce district heating distributed by a 925-meter-long low-pressure hot water network, enabling the local authority to avoid using oil-fired heat during peak winter consumption, to stop using biomass boilers in summer, and to heat the equivalent of 1,150 homes.

The project has received a grant of 1.4 million euros from ADEME and 650,000 euros from the Occitanie region. It also helps to anchor the region in a logic of sustainable development and, above all, to secure the future of the employment pool, as ArcelorMittal is the department’s largest industrial employer.