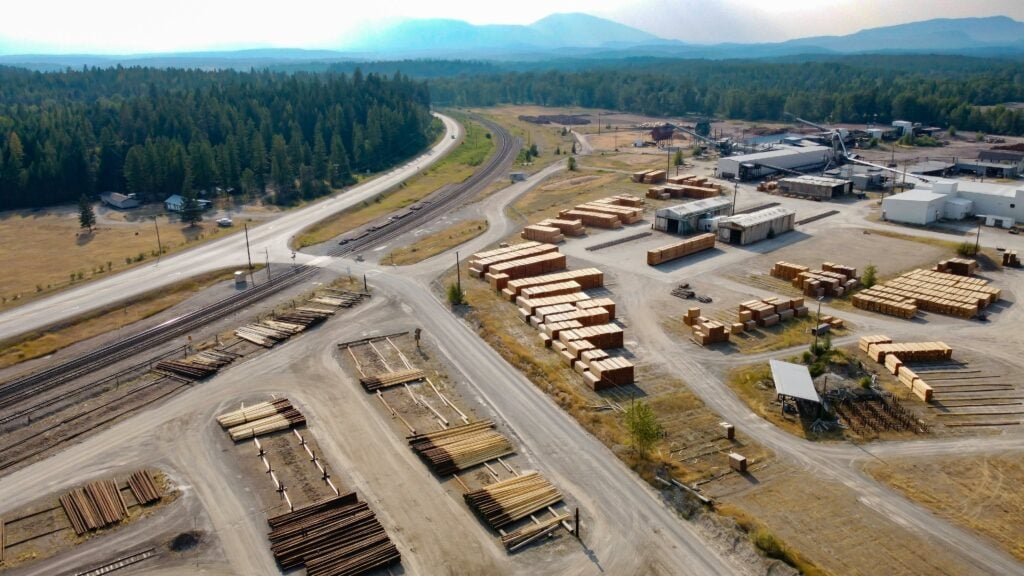

This project is the result of the acquisition in March 2020 of a biomass cogeneration plant commissioned in 2017, comprising a 720 kWe, 3 MWth ORC system. Alongside this acquisition, Kyotherm financed the construction of a new wood pellet production line with a capacity of 5 tonnes per hour, equivalent to 40,000 tonnes per year.

A second phase of the project was signed in September 2022. This will extend the site’s production capacity to 80,000 tonnes per year.

As part of this additional phase, two biomass boilers with a capacity of 2 MW and several pieces of equipment (grinder, dryer, silo, storage area) have been installed on site.

This project benefits from the Renewable Heat Incentive support mechanism set up in 2011 in the UK to promote the development of low-carbon heat production projects in the country.